Multi Micro Structure™ Technology

The increasing request from customers of three-dimensional composite wing membranes ensures that the current productive cycle is mainly oriented to this kind of product.

The three-dimensional membrane offers different benefits compared to the flat one, as it displays curvings and shapes that differently should be conferred through joints or seams of flat panels conveniently shaped. From a structural point of view, also, the lack of joints or seams ensures that the structural frame is continuous and not discontinuous conferring to the product a monolithic structure. That results also in advantages in terms of weight not being necessary overlaps for the joints.

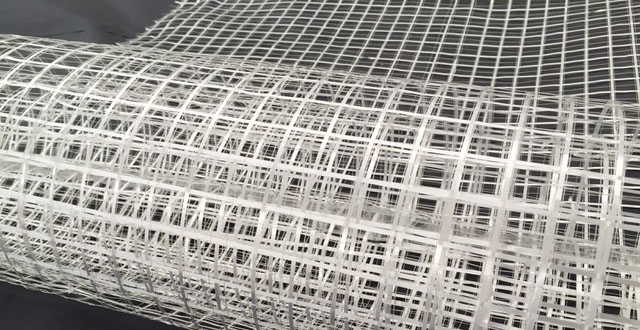

This kind of membrane, as opposed to the flat ones made with the use of simple calenders, requires productive stages that must combine accuracy to the shape of the project, industrial automation and craftsmanship of the production technicians in positioning the fibers of the structural frame. Upstream of these stages it occurs the structural calculus that restores the mix of the layers and the density of the structural fibers on the basis of the loads and the requested features of stiffness. Only by way of example a few tenths of millimeter composite membrane can contain inside even more than twenty micro layers each of which is able to confer particular features to the final product.

The semifinished product, once assembled, undergoes a care process in a computer-assisted furnace that can host one-piece products up to 300 sqm of size, so that through the temperature sensors it is possible to check and discriminate the temperature in each area within a few tenth of degree. The fusion of all layers inside the furnace takes place at vacuum pressure beyond nine tons for sqm.

It must also be pointed out that, unlike the production of flat membranes where it is possible to find machineries, tools and productive know-how on the market, these are procedures and manufactures that are currently realized by a few companies worldwide, each of which, just like Flexon Composites S.r.l., designes and realizes independently the machineries that, as well as techniques and stages of the production process, are the subject of the most strict trade secret.